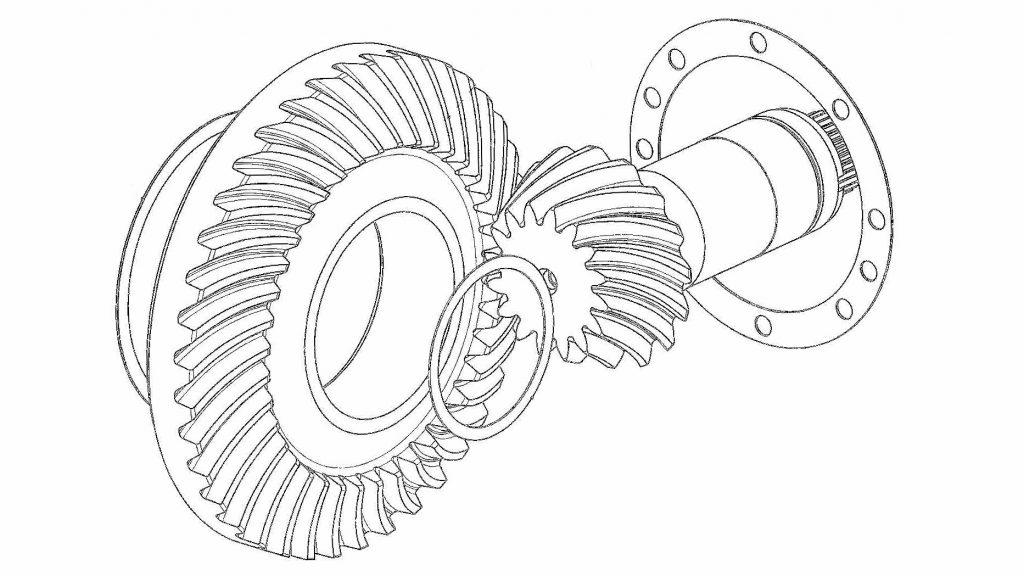

So that the shafts are precisely aligned

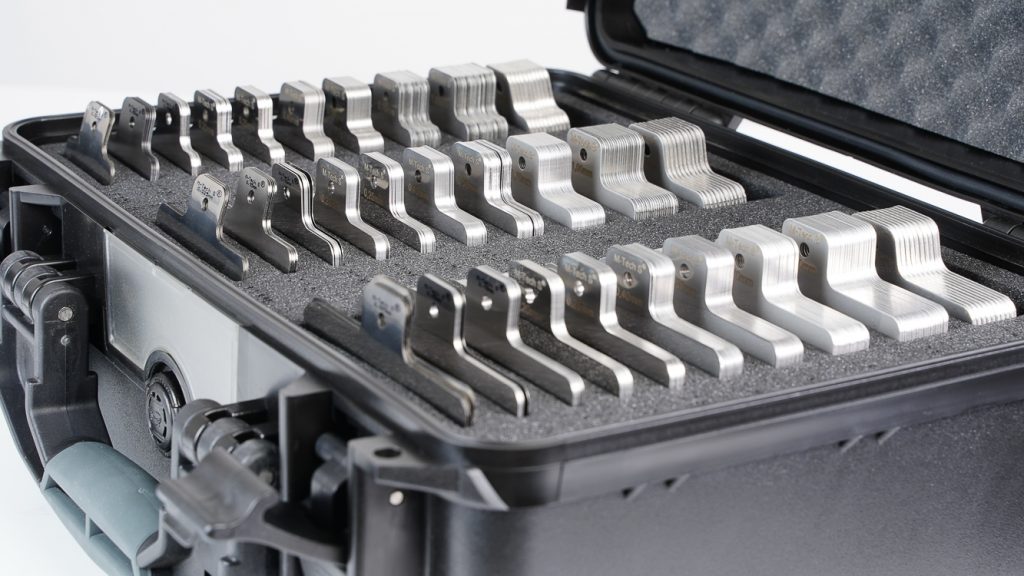

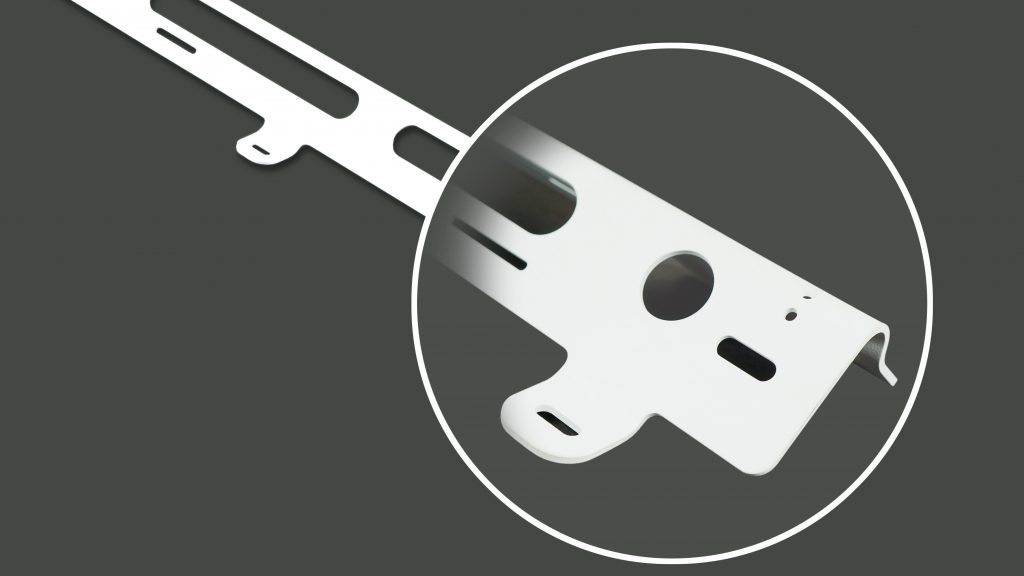

Customized shim assortments from MARTIN simplify alignment work 📷 Example of a special sealing made of plastic Wherever precise alignment, levelling and compensation of shafts,

+49 6074 4099 0

info@georg-martin.de

Martinstrasse 55

63128 Dietzenbach

Germany

Laser cutting, CNC Stamping, Water jet cutting, Machining and many more

Bending, Punching, Deep drawing,

In-House Toolmaking

Bonding, Screwing, Riveting, Pressing

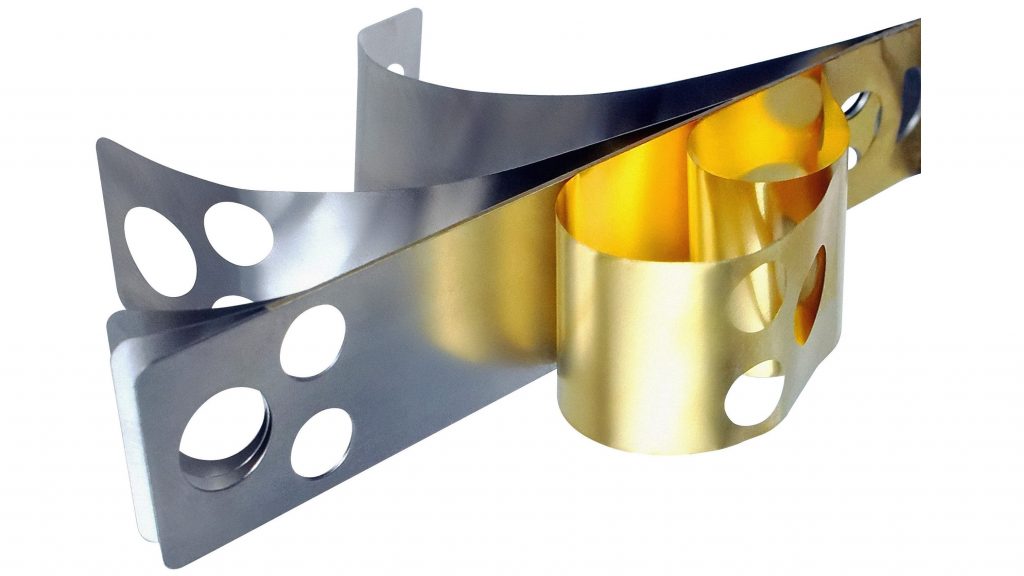

We have been manufacturing metallic shims for tolerance compensation as well as punched and deep-drawn parts for mechanical and plant engineering applications for more than 75 years.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

We manufacture flat and three-dimensional parts according to your specifications or we can be in charge in the development for you.

We also integrate fine laser cutting as well as the cutting of sheet metals with thicknesses of up to 6 mm.

Special designs and industry standard formats in high quality

On the basis of our core competences of punching and forming technology

In addition to our customer-specific products, we also have a large selection of standardized M-Tech® solutions in our portfolio

The combination of the characteristics of a company makes all the difference. In order to be able to effectively meet customer requirements, we think along with you. Our customer service representatives and tool designers get through your requirements in order to implement them in the best possible way:

Diverse processes, materials and batch sizes and special processes.

When manufacturing products, we draw internally from a wide variety of different processes. We establish for you which type of production is at optimal cost.

We at MARTIN® also contribute to the process of exchange and therefore to the solution of problems. With our specialized products, which are often customized to a specific task, we are capable of promoting successful and profitable solutions.

Customized shim assortments from MARTIN simplify alignment work 📷 Example of a special sealing made of plastic Wherever precise alignment, levelling and compensation of shafts,

As a premium manufacturer of flexible shims, customer-specific formed parts and self-adhesive decorative overlays, MARTIN processes an ever-growing selection of metal foils and precision sheets.

MARTIN producing oversized shims for use in heavy-duty gearboxes Precision shims from MARTIN’s Laminum® series are being recognized more and more in many sectors

The standard delivery time is 20 working days for drawing parts. Express delivery is possible on request and will be examined individually for feasibility.

For an inquiry, we require:

We only require total thickness, adjustment range and adjustment accuracy for setting tasks.

Georg Martin GmbH

Martinstrasse 55

63128 Dietzenbach

Germany